"Nature does great work without expecting any reward", is a phrase from the Russian philosopher Aleksandr Ivánovich Herzen, which, at this time, we can extrapolate to the vineyard, a project that began to sprout in spring and will soon mature bunches.

From this moment, the harvest date, the work in the reception and care of the grape, the must and the wine are the tasks to master to make a wine you’ll love.

A tool that helps us make decisions regarding the harvest is the Dualex, thanks to this optical sensor, we can find out the nutritional level of the vineyard between flowering and harvest, sufficiency or deficiency of N.

The nutritional quality of the must defines the organoleptic quality of the wines. Its composition can vary between 40-400 mg YAN, depending on soil deficiencies, water stress and/or imbalances in the plant that will cause the nitrogen content of the grape to vary.

If the must is deficient, we will have a wine lacking in freshness and intensity, the measurement with Dualex allows us to anticipate, we still have time to add some N and S during foliar harvest.

We know that a defined wine profile can only be achieved with a specific grape profile. Therefore, the care of the vineyard must be aligned and reflected in the product we want to design, we save everything that comes standard in the winery.

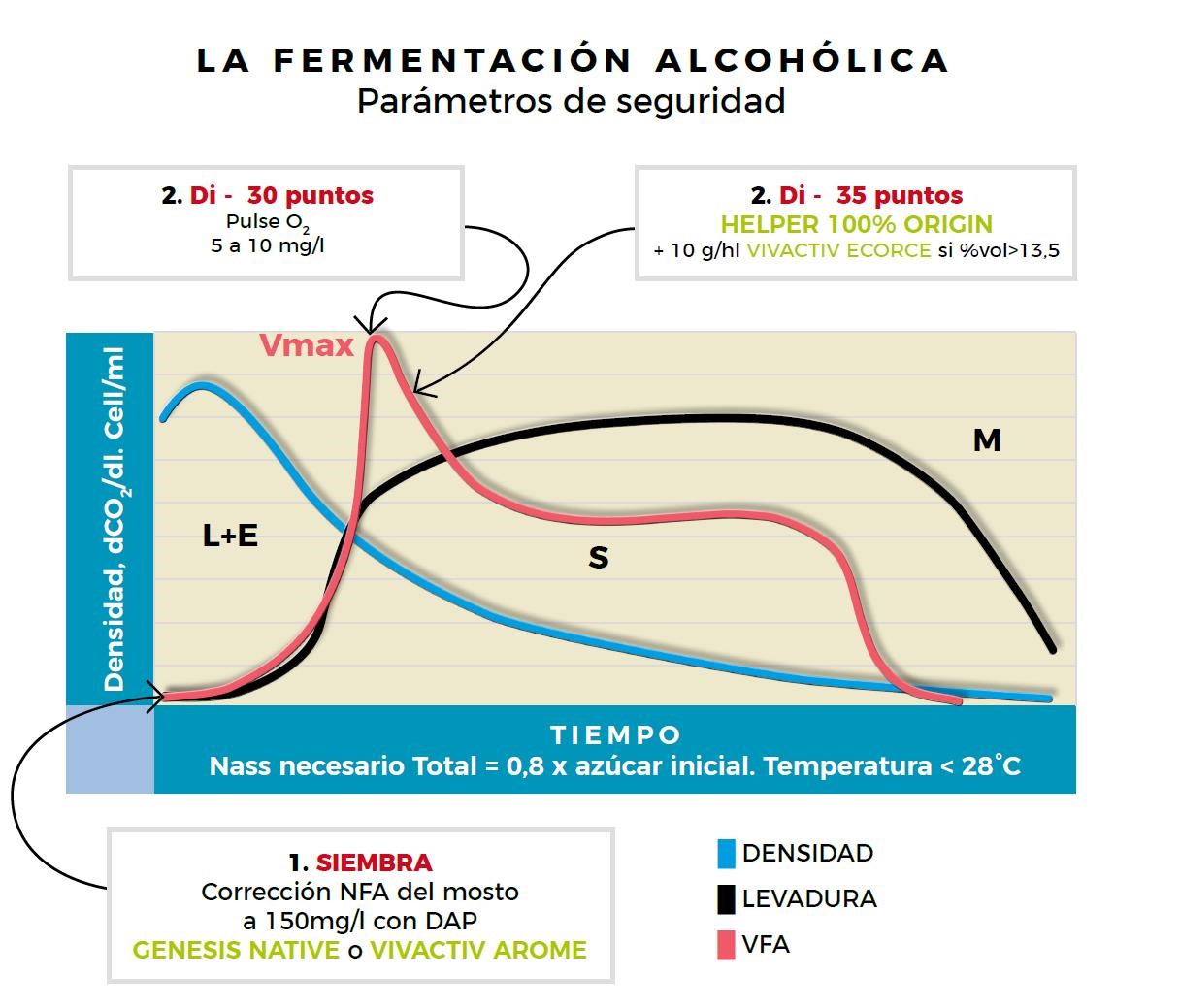

The key stage is fermentation, here we can ensure 70% of our success. Apart from choosing the right yeast strain, or multiplying a reservoir of successful yeasts for the vintage (Vintage project ) we have to ensure that the fermentation follows the precise dynamics to express the identity of each vineyard.

For this reason, the management of temperature, turbidity, oxygen and nitrogen are equally important both for the proper development of the fermentation and for the aromatic quality of the wine.

The enology that we propose here is living enology, with preventive solutions to anticipate possible risks and thus be able to avoid them.

NITROGEN: Natural is always best.

To successfully conduct AF, it is necessary to measure YAN levels during maturation controls and upon arrival at the winery.

To ensure proper multiplication, it is necessary to start any AF with more than 150 mg/l of YAN (this amount is based on the YAN needs to ferment a must with a potential of 12º in 8 days at 24ºC.) Otherwise. we will not have a good multiplication and there will not be enough population to end the AF with guarantees. If there is a deficiency, this should be corrected with ammonium salts due to their direct action on cell multiplication. If there is no deficiency (>150 mg/l), it is best not to feed initially. Yeasts have a small stomach, so it is not advisable to apply more DAP than the corresponding amount.

However, when VMAX is reached, the moment of maximum fermentation speed when the initial density drops approx. 30 points, this coincides with the maximum population of yeasts and there is a metabolic change, because they stop multiplying, and face an increasingly hostile environment (Vmax). At this point, the yeasts have consumed the majority of the nitrogen that was available. The oxygen supply in a timely and rapid manner will help facilitate the assimilation of organic nutrition and the survival of yeast at the end of AF.

After oxygen, when the density has dropped 35 points, it will be time to add the organic nutrient. This means the yeast will incorporate it more easily into its metabolism and we will be able to provide essential micronutrients (vitamins, peptides, lipids and minerals) that are not present in inorganic nutrients. In addition, organic nutrients help improve balance in the mouth, with rounder and more persistent wines.

If fermented to >13.5% alcohol or in other adverse conditions, the use of yeast bark early improves the end of AF a lot. 10 g/hl of yeast bark along with the organic nutrient is enough to ensure a happy ending, 20 g/hl when the AF has already slowed down is a waste of money.

The really important thing in the care of AF is TO MEASURE and act accordingly. If, on the other hand, we use a recipe, we run two important risks:

- If we overnourish the must, we are stimulating the production of volatile acidity and penalizing the synthesis of higher alcohols and their corresponding esters. In addition to wasting thousands of refrigeration units.

- If we fall short by cutting costs, we see how the aromas disappear in the 5 days to finish the last 15 grams.

It is sensible to work preventatively, that is to say measuring and feeding the years at 2 points (if the must only reaches >150 mg/l of YAN at VMAX), to avoid slowdowns, aromatic deviations and to save time and energy consumption.

We have spent 20 years monitoring fermentations.

Click for more info.

Related news

“Vintage” knows your vineyard

The sowing of selected industrial yeasts in the history of winemaking is a rather recent technique, very widespread in current enology because it provides fermentation safety (controlling other variables such as nutrition, temp.) and specific organoleptic profiles (valued in some markets) but that some reject because it may involve standardization of the product.