Who has not experienced reductions during alcoholic fermentation, with the consequent loss of aromatic quality, and its corresponding economic loss?

Yeast metabolism involves a significant number of biochemical reactions, which can modify the secretion of the final product in very different amounts, thus altering the sensory profile of the wine.

The management of oxygen and nutrient inputs not only has an impact on the kinetics of fermentation, but also on the aromatic quality of the wine. By-products of yeast metabolism have been shown to participate in the aromatic profile and are bound to nitrogen sources in the medium.

During the last 10 years, we have carried out numerous tests that demonstrate the strong impact of oxygen and nutrient inputs during fermentation on the final product.

Therefore, temperature management, turbidity , oxygen and nitrogen are important both for the proper development of fermentation, and for the aromatic quality of the final product.

One of the most significant aspects to interpret in the composition of the grape is its content of amine and ammonia nitrogen. This parameter gives us valuable information about the wine profile that we can obtain and at the same time how to nourish the yeast.

Current enological trends and the high maturity stages that are sought in grapes often make yeasts work under difficult conditions, and they will not be able to carry out successful fermentation if we do not provide them with adequate nutrition.

Living enology is an enology that anticipates. In this case, to anticipate reductions in fermentation, it is necessary to provide the yeast population with adequate nutrition. 80% of fermentation problems can be avoided by correctly managing the supply of Nitrogen and Oxygen in the musts at the most opportune moment for it.

For an optimal yeast population (100 million/cell/mL), the musts must start the fermentation with 150 mg/L of YAN, otherwise, there will not be good multiplication of the yeast.

If we need to correct the parameters, we will resort to ammonium salts, which have a direct impact on cell multiplication. However, this should not be exceeded since it would cause temperature peaks, population excess and subsequent denutrition of the population.

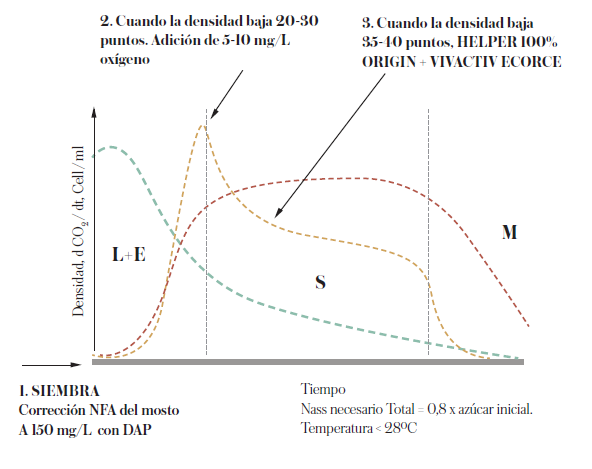

From the graph we can see that the fermentation speed has a maximum. At this point, changes will occur in the yeast's metabolism, and this will be the moment of maximum fermentation rate Vmax, which is when the yeast stops reproducing and prepares for the stationary survival phase.

The Vmax concept

Although alcoholic fermentation is an anaerobic phenomenon, we know that yeasts need minimal amounts of oxygen to survive, resist fermentations, and above all, high alcoholic strengths.

The works of Jean Marie Sablayrolles (Instituto National de la Recherche Agronomique) have verified that the curve showing the fermentation kinetics is a curve characterized by a peak of maximum fermentation speed (Vmax), followed by a regular decrease in activity.

This Vmax is a fundamental stage of fermentation, since it is the moment of the active growth phase from which the yeasts prepare for the stationary survival phase.

This stationary phase represents between 2/3 and 3/4 of the duration of fermentation, during which the yeasts are much more sensitive.

The timely and rapid delivery of oxygen (6 hours) must be carried out at this moment immediately and completely (when the initial density drops 20-30 points). The oxygen supply rate must be lower than the consumption rate.

This time is when yeast needs oxygen to promote the biosynthesis of lipids, sterols and unsaturated fatty acids, which are part of the composition of the cell membrane. Therefore, we will be able to achieve impermeability to alcohol, guaranteeing a happy ending to the fermentation and reducing the risks of H2S appearing during the process.

Considering that the air does not have more than 21% oxygen, compressed air applications, aeration or perforated steel pipes are NOT effective. It will be much more effective to apply pure oxygen through a ceramic (macro-oxigenador, Cliqueur).

After the oxygen, when the density has fallen 40 points, this is the time to add the organic nutrient. This means the yeast will incorporate it more easily into its metabolism and we will be able to provide essential micronutrients (vitamins, peptides, lipids and minerals) that are not present in inorganic nutrients. In addition, organic nutrients will help improve the balance in the mouth, with rounder and more persistent wines.

We can say that each nutrient will be suitable for each stage of fermentation, thus managing to feed the yeasts in the best way so that they enhance the secrets of our grapes.

Related news

Oxygen: friend or enemy?

These days, with the level of knowledge that we accumulate of all those reactions in which O2 plays an important role, we are clear that the management of this element in the winery is essential to be successful in obtaining the target wine profile.